Vibrating trough conveyor with unbalanced motor

Description

Vibrating conveyors with unbalance drive are widely used due to its simple basic construction in many industries and applications. They are used to transport various materials to be conveyed over shorter distances. The various applications range from bulk material discharge from bunkers and silos to foundry sands conveying to metal scrap removal from shredders or shears.

CYRUS Vibrating conveyors with unbalance drive are designed project-specific to customer requirements, designed and integrated into your complete line. Due to the variety of applications, this type of vibrating conveyor is available in countless varieties and with many options.

Below we have compiled some information about this base product of the vibrating conveyor technology. A complete description of all options would go beyond the scope - we are pleased to present you the optimally tailored application through personal contact.

The machines operate with low wear, are characterised by gentle product handling and are distinguished in particular by these characteristics:

- Long service life, high operational reliability, even in tough applications

- Minimum operating costs through low-maintenance operation

- Wide range of applications through countless variations and options

- Sophisticated technology, proven in thousands of applications

- Particularly favourable value for money

CYRUS comes back on the experience of over 200 delivered vibrating conveyors with unbalance drive. Also for your needs we will find the right solution. Challenge us!

Application

Typical areas of application for vibrating conveyors with unbalance drive are:

- Discharge of bulk material from bunkers and silos

- Charging of crushers, mixing machines, furnaces, weighing machines, screening machines etc.

- Conveying of foundry sand from cast/sand separation to sand preparation

- Discharge of metal scrap under shredder and behind scrap shears

- Feeding to magnetic drums for separating of metallic parts during material flow

- Material transport in processing and sorting plants

The variety of applications is nearly unlimited - wherever bulk materials continuously or in batches quantities are to be conveyed over shorter distances, vibrating conveyors with unbalance drive come into operation.

Material: fine-grained bulk material to piece goods

Capacity: usually up to 1.000 t/h, in rare cases also above

Design size: trough areas to approx. 3.000 mm width and 8.000 mm length

Arrangement: sloped, horizontal, slightly inclined

Of course, larger conveying distances can be overcome by connecting several vibrating conveyors with unbalance drive. You need a larger conveying length and want to avoid transfer points? Then we recommend our vibrating conveyors with slider-crank drive (so-called "resonance trough conveyors"). These can be designed in individual lengths up to 50 m.

A selection of typical products, which often are transported be means of vibrating feeders with unbalance drive:

- Foundry used sand

- Casting parts

- Stones

- Metal scrap

- Waste slag

- Glass

- Animal feed

- Coffee beans

… and soon also your product ?

Technology

The vibrating conveyor can be designed depending on the application as a vibrating conveyor in trough shape or e.g. as a closed vibrating tube. The conveyor trough will be put into vibration by rotating unbalance masses. The mode of vibration of the trough can be influenced within wide limits by design, arrangement and quantity of drives.

Depending on tasks in CYRUS vibrating conveyors with unbalance drive different types of drives are used:

- Vibration motor

- Circular drive

- Cell drive

- Straightening exciter

We are looking forward to explaining you in personal contact more about the properties, application possibilities and limitations of the different drive types.

CYRUS vibrating conveyors are designed for continuous operation. The rugged welded- / screwed construction in vibration-resistant design are usually made of mild steel material. Designs in special materials are available. For the transport of abrasive materials, troughs made of wear-resistant special steels are also used. Screwed or welded wear liners can also be provided, whereupon the wear protection material is matched to the material and the particular application.

Variants, options, special designs:

- Influencing of conveying speed by frequency control of drives

- Electronic gear for adjusting the vibrating angle during operation (details)

- Exchangeable lining made of wear-resistant special steel

- Heavy design, suitable for explosions in the shredder

- Stop rails and safety catches

- Vibration monitoring via acceleration sensor

- Trough bottom heating to avoid caking

- Bunker discharge chute

- Needle slider

- Hoods and covers

- Dust seals

You miss a variant or option? Contact us; we have surely the right solution for your application.

Projects

Aus der Vielzahl gelieferter Maschinen haben wir hier ein paar typische Beispiele für Sie zusammengestellt:

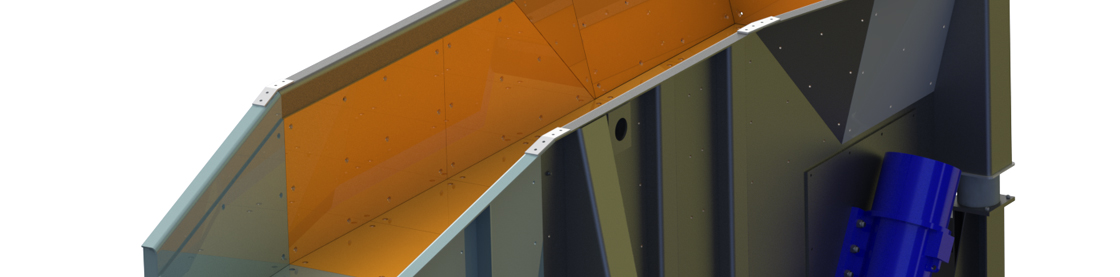

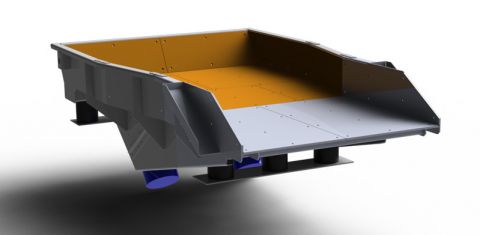

Sand Conveyor Trough, foundry (picture 1)

| Type | CYRUS SRU 1.000 x 6.000 |

| Material | Foundry used sand |

| Conveying capacity | 150 t/h |

| Design size | Width 1.000 mm x length 6.000 mm |

| Characteristics | Lining made of wear-resistant special steel |

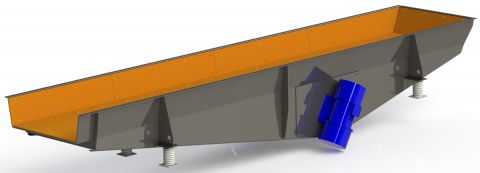

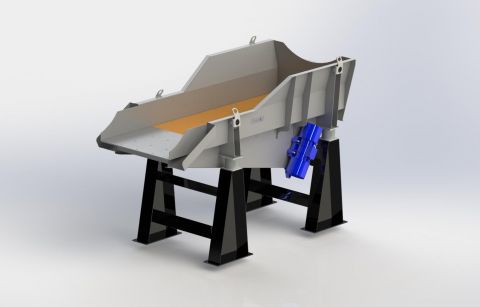

Bunker Discharge Trough, Mining (picture 2, 3)

| Type | CYRUS SRU 1.200 x 3.200 |

| Material | Iron ore, grain size 0-300 mm |

| Conveying capacity | 750 t/h |

| Design size | Width 1.600 mm x length 3.500 mm |

| Characteristics | High conveying capacity Lining made of wear-resistant special steel Heavy design with wear protection Slope 8° Layer thickness limiter Trough bottom heating for cryogenic application Vibration motors with standstill heating Bunker discharge chute with needle slider Dust seals |

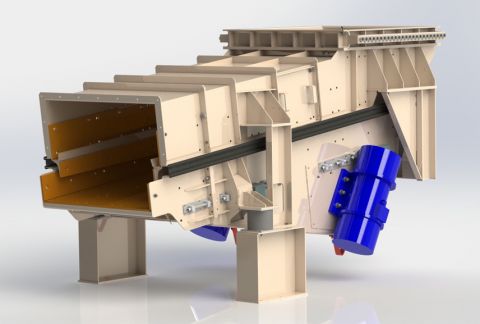

3) Shredder Trough, Metal Recycling (picture 4)

| Type | CYRUS SRU 2.200/2.600 x 8.000 |

| Material | Metal scrap, shredded |

| Conveying capacity | 300 t/h |

| Design size | Width 2.200 / 2.600 mm x length 8.000 mm |

| Characteristics | Conveying under the shredder Especially heavy design Machine weight approx. 21 t Lining made of wear-resistant special steel |