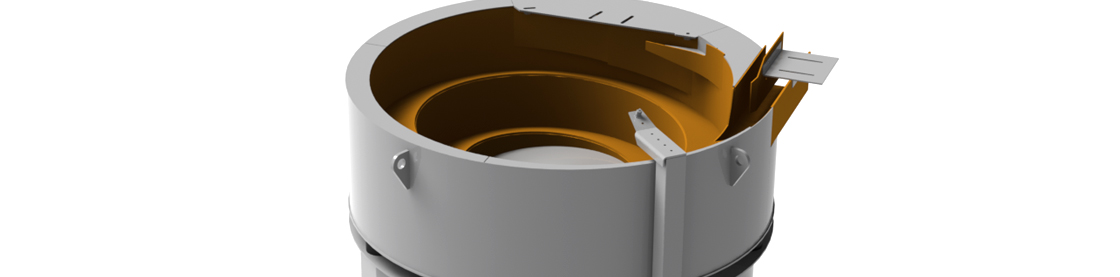

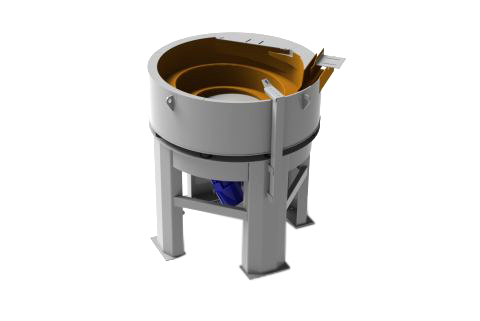

Spiral billet charging machine

These systems basically comprise a metering machine and theup and downstream system components like tilting device, storagetrough, roller conveyor or vibratory trough conveyor with magneticdrive. Automatic metering machines are used to handle andunmatch billets. Diametrically arranged vibration motors providedrive. The main group of metering machines are so-called»inside-spiral« designs (pot with internal spiral). Pots with external sorting spiral are also available for specific customer requests.

Features

- Compact design

- High wear-resistance

- Rugged design

- Complete solutions

- Low noise operation

Benefits

- Low operating costs

- High operational reliability

- Long service life

- Good value for money

- Reduces the noise emissions of the plant

Technical specs

- Various sizes of sorting pots up to 2.800 mm in diameter

- Various sizes of storage troughs up to 10 t of bin capacity

- Optional also swivel-type storage troughs

- Optional tilting devices

- Optional roller conveyors

Application

- Charging systems for induction furnaces in forging shops

- Material conveyed: steel round or square billets

- of different dimensions.

- In the industry: forging shops